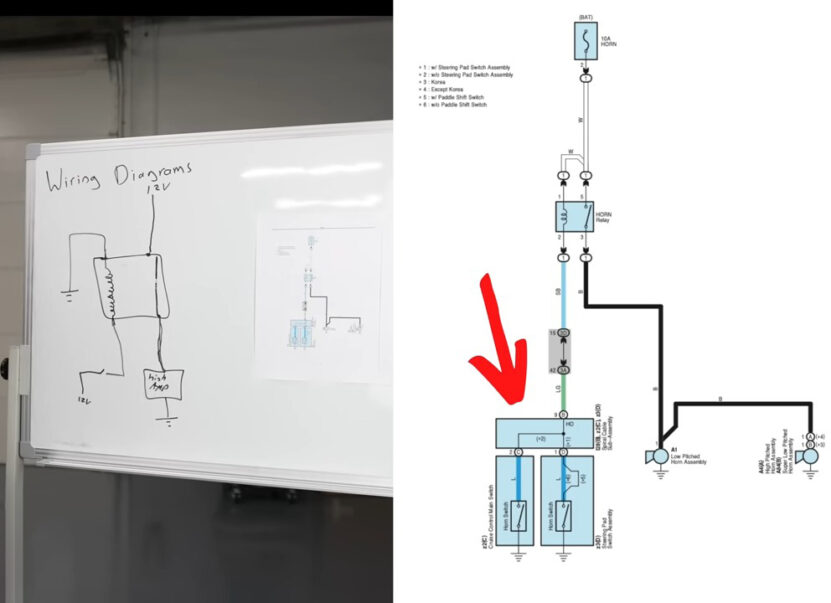

Navigating automotive wiring diagrams might initially appear daunting, but with a grasp of the fundamentals and assistance from an online mechanic, you can address the majority of standard car electrical issues. Wiring diagrams are invaluable tools in diagnosing vehicle malfunctions.

When utilized effectively, these diagrams can significantly reduce the time spent pinpointing issues, as they provide a comprehensive view of your engine’s components. Yet, many individuals find themselves overwhelmed when confronted with these intricate diagrams.

To demystify the process and empower users, we offer a detailed guide on understanding and applying automotive wiring diagrams to your troubleshooting endeavors.

Main tasks when using automotive wiring diagram

Like any vehicle ECM (engine control module) wiring diagram, the entire terminal pins of the computer module are shown in the ECM wiring diagram. It is usually displayed on the first page of the diagram as a box with all wiring harnesses going in and out of it.

The only thing to remember is the discussed in the topics below when you look at your vehicle wiring diagram.

Source of power supply

Usually 12 volts and mostly protected by a fuse, the wire color is usually red and must be handled with care. If accidentally touched or shorted with the ignition key on, it can damage the engine computer or the components it is connected to.

When testing for a power supply, you can either use a digital volt meter or a test light. If you are starting out, a cheap voltmeter can be bought for under $20 but if you plan to do a lot of troubleshooting, a good brand can be bought for around $50 which can have different features like testing the resistance, dwell, and other functions which can help you troubleshoot faster.

A test light with low impedance is also advisable so you can avoid damaging any sensors or even the ECM wiring or module itself. This holds true when buying a digital voltmeter.

Automotive wiring diagram tip #1

When making a power supply test, always begin by testing your voltmeter or test light. This can be done by testing the battery terminals.

If you have a good battery, you should get 12 volts or if you use the test light, it will light up.

Ground wire supply

Ground wire connections are usually black in color and can be tested by measuring their voltage against the body frame or battery-negative terminal. The Max voltage reading is 0.250 volt and anything higher means a short in the system.

When measuring the ground supply, connect the ground lead to a clean ground supply like the battery negative terminal or the vehicle frame. The positive lead will go to the negative supply or ground wire of the sensor or component you are testing.

Ground testing is actually a good way to test if your ECM wiring is working because its (computer module) main function is to deliver ground supply.

Automotive wiring tip #2

When testing a ground supply of the ECM wiring, always turn the ignition key on. When testing your engine computer, you can actually remove it completely from the system and reconnect the battery and you can isolate the wiring system for any short.

With the battery connected, test the ground wires and if any reading is above 0.250 volts, you know your computer is OK.

Voltage Reference Wire

A reference voltage is generated inside your engine computer. Common value is 5 volts and could go as high as 10 volts on some engine applications. When testing, the ignition key is usually turned on with the engine off and all the computer terminals connected.

If you exceed the designated voltage value, it usually denotes an electrical problem either from the computer itself or one of the sensors. You can test the reference voltage quickly by disconnecting the sensors or components one at a time until the voltage reading returns to normal.

Automotive wiring diagram tip # 3

After you disconnect any sensor or component with a key on the engine off, it is a good practice to disconnect the battery negative terminal after the test. This will reset the code in case it was triggered when the sensor/component was removed.

Testing component sensors

Testing sensors can be made by measuring the power supply, ground, and voltage reference going to it. When in doubt, it can be removed and compared readings with a new one to verify.

As with any engine component, they can be replaced if they have too many hours. This goes especially to oxygen sensors which start to become lazy when used more than after 2-3 years and which can affect your fuel mileage.

Automotive wiring diagram tip # 4

Most sensor functions can be easily understood if you have a wiring diagram that will show the path of the sensor circuit. Looking at the automotive wiring diagram as a whole is really very intimidating but if you try to isolate each circuit or individual sensor circuit, then it is easier to solve.

As long as you are a member of ATS, there will be a licensed mechanic who will assist you whenever you need help.

FAQ

What is the primary purpose of an automotive wiring diagram?

An automotive wiring diagram provides a visual representation of a vehicle’s electrical system, allowing for easier troubleshooting and understanding of the vehicle’s components.

Do I need special tools to read and understand these diagrams?

While having tools like a voltmeter can be beneficial for practical applications, the primary requirement for understanding a diagram is knowledge and patience.

How often do wiring diagrams get updated?

Wiring diagrams are typically updated with each new vehicle model or when significant changes are made to existing models.

Can I rely solely on online mechanics for troubleshooting using these diagrams?

While online mechanics can provide valuable guidance, it’s essential to have a foundational understanding of the diagrams for the most effective troubleshooting.

Are there different types of wiring diagrams for different vehicle systems?

Yes, vehicles have multiple wiring diagrams, each corresponding to different systems like lighting, engine controls, and entertainment systems.

How do I know if a sensor is faulty or if it’s a wiring issue?

Testing the power supply, ground, and voltage reference to the sensor can help determine if the issue lies with the sensor itself or the wiring.

Where can I find the wiring diagram for my specific vehicle model?

Most vehicle service manuals contain wiring diagrams. They can also be sourced from the vehicle manufacturer or specialized automotive publications.

Final Words

Understanding automotive wiring diagrams is akin to deciphering a new language. While it may seem complex at first glance, breaking it down into individual components and circuits makes the task manageable.

With the right tools, knowledge, and guidance, anyone can navigate these diagrams and address car electrical issues. Remember, every intricate system is just a series of smaller, understandable parts.

With patience and practice, you’ll find that these diagrams become less of a puzzle and more of a roadmap to vehicle troubleshooting.